- Home Page

- Company Profile

-

Our Products

- Electronic Relays

- Advance Feeder Protection & Monitoring Ied : Csezen-f550

- Directional Overcurrent Relay

- AMF Relay

- Frequency monitoring relay series

- Electronic Motor Protection Relay

- IRM-Pro Relay

- PTC Thermistor Relay

- Voltage Monitoring Relay series

- Relay Electronic

- Earth leakage Relay

- Engine Control Relay

- MPR 200nX & 300

- EC 2 AMF Relay

- MN Relay

- RTO Relay

- RX RELAY

- ML Relay

- Current Monitoring Relay

- Ground Fault Module

- SMDBs for Power Distribution

- Low Voltage Switchgears

- ML Contector

- HRC Fuse Link & Base

- Power Capacitor

- Power Quality Solution

- Standard Illuminated Actuator with LED

- Panel Mounted Buzzer

- Electromechanical Timer

- Digital Time

- Digital Timer Digicon

- Gen Next Push Button

- Gen Next LED Indicator

- TPN DB

- SPN DB (Distribution Board)

- Single Phase ACCL

- Surges Protection Devices (SPDs)

- 4 Pole Isolators

- Servo System

- Programmable logic controller (PLC

- AC Drive

- etaCON M-APFC Controller

- HF fuse DIN-HN Fuse HG and HQ Fuse Bolted

- FNX TPN S-D-F

- FN-TPN S-D-F Suitable for BS Fuse Link

- Type FN S-D-F Suitable for DIN Fuse-link (2P) in Open Execution

- Motor Protection Circuit

- FN-TPN S-D-F in SS Enclosure

- Motorised Changeover

- CONTECTOR 4POLE 25A~125A

- DISTRIBUTION BOARD

- MDX (DC CONTROL)CONTECTOR

- RCCB 2Pole 10-100AMP

- Indicator Lamp

- Fuse Link Cns Off Set Clip In Type 2-20amp

- RCCB 4POLE 10-100AMP

- Hrc Fuse

- Fuse holders suitable for Cylindrical / DIN / Bolted fuse-links

- APFC Controller

- Active Harmonic Filter (AHF)

- PPI DB (Distribution Board)

- Medium Voltage Switchgears

- Circuit Breaker

- Isolators / Mcb

- MCCB (1600AF)

- mccb circuit

- Moter protection circuit Breakers

- Air Circuit Breaker

- Mccb Du/dy

- MCCB 3 POLE 63A-400A

- Mccb Single Pole 16a~160a

- MCCB 4 POLE 63A-400A

- DY 125U MCCBs

- OMEGA Breaker

- C-Power OMEGA Breaker

- Residual Current Circuit Breaker (RCCB)

- Residual Current Circuit Breaker (RCCB)

- MCB 3Pole 6-63Amp

- Mcb 2pole 6-63amp

- Mcb Single Pole 6-63amp

- Mcb 4pole 6-63amp

- Miniature Circuit Breaker (MCB)

- RCCB 1

- SURGE PROTECTION DEVICE

- MCB 2

- Microprocessor Release MicroPro WB

- MCCB Frame S

- WiNbreak2 MCCB

- ACE 2 MCCB

- MCCB - CS Series

- MCCB - CSC Series

- Automatic Changeover With Current Limiter (ACCL)

- MCCB With Thermal - Magnetic Release

- MCCB With Microprocessor Release

- MCCBs for Motor back-up Protection

- Electrical Switches

- 32A Switch Disconnector

- On Load Changover Switch

- one way switch 6A~25A

- SWITCH Disconnector Fuse

- BELL PUSH SWITCH

- Changeover & By Pass Switch

- Switch Disconnector 32a`800a 2p~4p

- Automatic transfer switch

- Change over switch

- Switch disconnector fuse

- FN & C-Line Switch disconnector (2P/TPN/4P)

- changerover switch

- Load Break Switch

- Rotary Switch

- DC Switch salzer

- Time Switches

- POWER UNIT

- Fan Regulator / Dimmer

- Power Bus Trunking

- Power Contactor

- robusTa Power Contactors

- ExceeD Contactor 6A-95A

- MX0(AC/DC)Auxiliary contactor

- MU -2 POLE CONTACTOR

- CAPACITOR DUTY CONTACTORS

- MN0 CONTACTOR (DC)

- MVO (VACUUM)CONTACTOR

- MI CONTACTOR 3POLE

- MX CONTACTOR

- MNX CONTACTOR 3-POLE

- MO CONTACTOR 3-POLE

- Mr Contactor

- MNX CONTACTOR 2 POLE

- CAPACITOR CONTACTOR

- mk1 & MK2contactor

- Power Contactor DX-Series

- Mini Contactors

- D Range Contactors and Overload Relays

- New AGRO 4 Pole Contactor Series

- Electric Socket

- PVC Cable Ducts

- Motor Starter

- Accessories

- Add-on Auxiliary Contact Blocks

- Connecting Links and Mechanical Latch

- Thermal Overload Relays

- Spares and Accessories for type FNX and FN

- SS Enclosure for MCCBs

- Accessories for DU/DY MCCB

- SMDB Accessories

- Accessories of OMEGA Air Circuit Breakers

- Accessories of C-POWER Air Circuit Breakers

- Accessories for Air circuit Breaker

- Accessories for MCCB - CSC Series

- Accessories for Switch Disconnector fuse

- Electronic Relays

- Contact Us

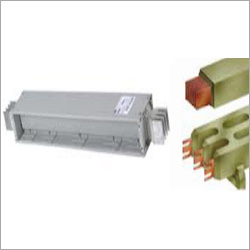

Bus Bar Lighting Trunking (32-63A)

Bus Bar Lighting Trunking (32-63A) Specification

- Mounting Type

- Ceiling Mounted / Suspended

- Usage & Applications

- Lighting, Commercial, Industrial, Office Spaces, Malls, Warehouses

- Thickness

- 1.01.2mm

- Surface Finish

- Epoxy Powder Coated / Pre-Galvanized

- Features

- Lightweight, Modular Design, Easy Installation, Corrosion Resistant

- Pole Type

- 3 Pole / 4 Pole

- Weight

- Approx. 2.54 kg/m depending on size

- Product Type

- Bus Bar Lighting Trunking

- Material

- Galvanized Steel / Aluminum

- Rated Power

- 32-63A

- Length

- 1m / 3m / 4m (standard available)

- Voltage

- 220-415V AC

- Lighting

- Supports suspended and surface lighting

- Input Voltage

- AC 230V/415V

- Working Temperature

- -5C to +40C

- Rated Current

- 32A / 40A / 50A / 63A

- Socket

- Optional tap-off outlets

- Color

- Silver / RAL 7035 Grey

- Height

- Approx. 60mm

- Tap-off Interval

- 1m or As Required

- Conductor Material

- Electrolytic Copper / Aluminum

- Short Circuit Withstand

- Up to 25kA for 1 sec

- Fire Resistance

- Up to 850°C (as per IEC 60439-2)

- Joint Type

- Bolt-on Joint With Insulated Cover

- Insulation Material

- High-Grade Flame Retardant PVC

- Max. Tap-off Points

- Up to 12 per length

- IP Rating

- IP54 (Standard)

About Bus Bar Lighting Trunking (32-63A)

Bus Bar Lighting Trunking (32-63A)

Lighting Trunking In addition to the varied range of products, we are offering a broad gamut of Lighting Trunking in various customized specifications. The lighting trunking is manufactured in compliance with the international standards using superlative quality raw materials that are sourced from the renowned vendors of the market. Tested on varied specific parameters, this Lighting Trunking is featured with accurate dimensions, reliable performance, durable finish and high strength.

Features

- From 7.5 mm x 7 mm to 100 mm x 230 mm

- Standard colours are pure white, cream, stone grey and light grey

- A wide range of fittings allows installations almost anywhere.

| Compliance of standard | IEC 61439 (1&6) and IS 8623 (1&2) |

| Independent certification authority | Central Power Research Institute (CPRI) |

| Busbar ratings | 25A, 32A, 40A |

| Busbar configurations | 2P-L1/N/PE(Housing) |

| 4P-L1/L2/L3/N/PE(Housing) | |

| 6P-L1/L2/L3/N1/N2/E/PE(Housing) | |

| 6P-L1/L2/L3/L4/L5/N/PE(Housing) | |

| 6P-L1/N1/L2/N2/L3/N3/PE(Housing) | |

| 8P/12P-As per client specifications | |

| Rated operational voltage (Ue) | 500 Volt, AC |

| Rated insulation voltage (UI) | 690 Volt, AC |

| Rated Dielectric voltage | 2.5 KV rms |

| Rated frequency | 50/60 Hz |

| Enclosure material | GI (thickness 0.5mm) |

| Surface coating on enclosure | Epoxy polyster powder coated(RAL-7032) |

| Busbar material (Phase/Neutral) | ETP grade copper 99.9% pure (Tin plated) |

| Integral Earth (PE) | GI Housing |

| Busbar insulation | Flame retardant PVC |

| Insulation thickness | 1.0mm |

| Joint | Inbuilt push flt joint at either end, (Comprises of copper contacts with pressure clip) |

Versatile Lighting Distribution

Designed for suspended and surface lighting applications, the Bus Bar Lighting Trunking system is suitable for commercial, industrial, and office spaces. Its flexible modular setup and various length options allow for tailored installations, making it highly adaptable to different project requirements.

High Safety and Fire Resistance

This lighting trunking meets rigorous fire safety standards, resisting temperatures up to 850C as per IEC 60439-2. The insulated bolt-on joints and flame retardant PVC insulation further protect against short circuits and fire hazards, ensuring operational reliability in demanding environments.

Efficient Installation and Maintenance

The lightweight and corrosion-resistant construction, combined with an easy bolt-on joint assembly, reduces installation time and simplifies ongoing maintenance. Modular design allows up to 12 tap-off points per length, supporting rapid system upgrades with minimal disruption.

FAQs of Bus Bar Lighting Trunking (32-63A):

Q: How is the Bus Bar Lighting Trunking system installed in commercial or office spaces?

A: Installation of the Bus Bar Lighting Trunking is straightforward and can be done by ceiling mounting or suspending the trunking. The modular bolt-on joint with insulated cover streamlines assembly, enabling quick setup without specialized tools, suitable for both new and retrofit projects.Q: What conductor materials are available for this trunking system and how do they affect performance?

A: Customers can choose between electrolytic copper and aluminum as conductor materials. Electrolytic copper offers superior conductivity and durability for high-demand environments, while aluminum provides a cost-effective, lightweight alternative for standard lighting applications.Q: When should I consider using the Bus Bar Lighting Trunking with a 32-63A rated current?

A: This system is ideal when your lighting installation requires distributed power management within the 32-63A range. Common use cases include large commercial buildings, warehouses, and malls, where modular tap-off intervals and high safety standards are essential.Q: Where can additional tap-off outlets be placed, and what is the maximum number per length?

A: Tap-off outlets can be positioned at 1 meter intervals or as required along each trunking length. Up to 12 tap-off points can be accommodated per standard length, supporting flexible lighting layouts and future system expansions.Q: What process ensures the fire resistance and safety of the trunking system?

A: The trunking is built with flame-retardant PVC insulation and complies with IEC 60439-2 for fire resistance, tested up to 850C. The systems bolt-on joints and protective insulation further safeguard against electrical faults and fire hazards.Q: How does the IP54 rating benefit the Bus Bar Lighting Trunkings operational durability?

A: An IP54 rating ensures protection against dust ingress and splashing water, making the system reliable for operation in environments subject to moisture or particulate contamination, such as warehouses and industrial areas.Q: What are the main advantages of using this lighting trunking over traditional wiring?

A: The modular Bus Bar Lighting Trunking allows faster installation, easier maintenance, better safety through effective insulation, and flexible system expansion. Its corrosion resistance, fire safety features, and multiple tap-off options contribute to long-term value in commercial lighting installations.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Power Bus Trunking Category

Bus Bar Trunking Air Insulted

Features : Compact design, high shortcircuit strength, fireretardant insulation, easy installation and expansion

Product Type : Air Insulated Bus Bar Trunking System

Rated Power : Available in various ratings from 25A up to 6300A

Input Voltage : 415V AC (other voltages available)

Usage & Applications : Industrial, Commercial, and Infrastructure Power Distribution

Length : Standard length 3 meters (custom lengths available)

Send Inquiry

Send Inquiry