- Home Page

- Company Profile

-

Our Products

- Electronic Relays

- Advance Feeder Protection & Monitoring Ied : Csezen-f550

- Directional Overcurrent Relay

- AMF Relay

- Frequency monitoring relay series

- Electronic Motor Protection Relay

- IRM-Pro Relay

- PTC Thermistor Relay

- Voltage Monitoring Relay series

- Relay Electronic

- Earth leakage Relay

- Engine Control Relay

- MPR 200nX & 300

- EC 2 AMF Relay

- MN Relay

- RTO Relay

- RX RELAY

- ML Relay

- Current Monitoring Relay

- Ground Fault Module

- SMDBs for Power Distribution

- Low Voltage Switchgears

- ML Contector

- HRC Fuse Link & Base

- Power Capacitor

- Power Quality Solution

- Standard Illuminated Actuator with LED

- Panel Mounted Buzzer

- Electromechanical Timer

- Digital Time

- Digital Timer Digicon

- Gen Next Push Button

- Gen Next LED Indicator

- TPN DB

- SPN DB (Distribution Board)

- Single Phase ACCL

- Surges Protection Devices (SPDs)

- 4 Pole Isolators

- Servo System

- Programmable logic controller (PLC

- AC Drive

- etaCON M-APFC Controller

- HF fuse DIN-HN Fuse HG and HQ Fuse Bolted

- FNX TPN S-D-F

- FN-TPN S-D-F Suitable for BS Fuse Link

- Type FN S-D-F Suitable for DIN Fuse-link (2P) in Open Execution

- Motor Protection Circuit

- FN-TPN S-D-F in SS Enclosure

- Motorised Changeover

- CONTECTOR 4POLE 25A~125A

- DISTRIBUTION BOARD

- MDX (DC CONTROL)CONTECTOR

- RCCB 2Pole 10-100AMP

- Indicator Lamp

- Fuse Link Cns Off Set Clip In Type 2-20amp

- RCCB 4POLE 10-100AMP

- Hrc Fuse

- Fuse holders suitable for Cylindrical / DIN / Bolted fuse-links

- APFC Controller

- Active Harmonic Filter (AHF)

- PPI DB (Distribution Board)

- Medium Voltage Switchgears

- Circuit Breaker

- Isolators / Mcb

- MCCB (1600AF)

- mccb circuit

- Moter protection circuit Breakers

- Air Circuit Breaker

- Mccb Du/dy

- MCCB 3 POLE 63A-400A

- Mccb Single Pole 16a~160a

- MCCB 4 POLE 63A-400A

- DY 125U MCCBs

- OMEGA Breaker

- C-Power OMEGA Breaker

- Residual Current Circuit Breaker (RCCB)

- Residual Current Circuit Breaker (RCCB)

- MCB 3Pole 6-63Amp

- Mcb 2pole 6-63amp

- Mcb Single Pole 6-63amp

- Mcb 4pole 6-63amp

- Miniature Circuit Breaker (MCB)

- RCCB 1

- SURGE PROTECTION DEVICE

- MCB 2

- Microprocessor Release MicroPro WB

- MCCB Frame S

- WiNbreak2 MCCB

- ACE 2 MCCB

- MCCB - CS Series

- MCCB - CSC Series

- Automatic Changeover With Current Limiter (ACCL)

- MCCB With Thermal - Magnetic Release

- MCCB With Microprocessor Release

- MCCBs for Motor back-up Protection

- Electrical Switches

- 32A Switch Disconnector

- On Load Changover Switch

- one way switch 6A~25A

- SWITCH Disconnector Fuse

- BELL PUSH SWITCH

- Changeover & By Pass Switch

- Switch Disconnector 32a`800a 2p~4p

- Automatic transfer switch

- Change over switch

- Switch disconnector fuse

- FN & C-Line Switch disconnector (2P/TPN/4P)

- changerover switch

- Load Break Switch

- Rotary Switch

- DC Switch salzer

- Time Switches

- POWER UNIT

- Fan Regulator / Dimmer

- Power Bus Trunking

- Power Contactor

- robusTa Power Contactors

- ExceeD Contactor 6A-95A

- MX0(AC/DC)Auxiliary contactor

- MU -2 POLE CONTACTOR

- CAPACITOR DUTY CONTACTORS

- MN0 CONTACTOR (DC)

- MVO (VACUUM)CONTACTOR

- MI CONTACTOR 3POLE

- MX CONTACTOR

- MNX CONTACTOR 3-POLE

- MO CONTACTOR 3-POLE

- Mr Contactor

- MNX CONTACTOR 2 POLE

- CAPACITOR CONTACTOR

- mk1 & MK2contactor

- Power Contactor DX-Series

- Mini Contactors

- D Range Contactors and Overload Relays

- New AGRO 4 Pole Contactor Series

- Electric Socket

- PVC Cable Ducts

- Motor Starter

- Accessories

- Add-on Auxiliary Contact Blocks

- Connecting Links and Mechanical Latch

- Thermal Overload Relays

- Spares and Accessories for type FNX and FN

- SS Enclosure for MCCBs

- Accessories for DU/DY MCCB

- SMDB Accessories

- Accessories of OMEGA Air Circuit Breakers

- Accessories of C-POWER Air Circuit Breakers

- Accessories for Air circuit Breaker

- Accessories for MCCB - CSC Series

- Accessories for Switch Disconnector fuse

- Electronic Relays

- Contact Us

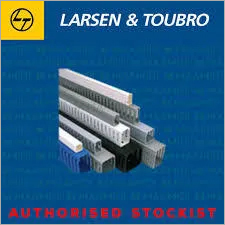

PVC Cable Ducts

PVC Cable Ducts Specification

- Conductor Material

- Non-conductive PVC

- Surface Finish

- Smooth

- Max. Working Load

- 30 kg

- Deflection

- <5 mm at max load

- Product Type

- Slotted PVC Cable Duct

- Material

- PVC (Polyvinyl Chloride)

- Standard Thickness

- 1 mm

- Length

- 2 meters

- Width

- 25 mm

- Side Rail Height

- 25 mm

- Weight

- Approx. 0.5 kg per meter

- Dimension (L*W*H)

- 2000 mm x 25 mm x 25 mm

- Color

- Grey

- Usage

- Wire and cable management in panels

- Packing Type

- Polybag or Box

- Design Features

- Slotted with removable cover

- Impact Strength

- Good

- RoHS Compliance

- Yes

- UV Resistance

- High

- Mounting Type

- Screw and adhesive

- Insulation Resistance

- >100M

- Halogen Free

- No

- Operating Temperature Range

- -10C to +60C

- Fire Retardant

- Yes, self-extinguishing PVC

- Suitable For

- Control Panels, Electrical Cabinets

PVC Cable Ducts Trade Information

- FOB Port

- JAIPUR, NEEMRANA, ALWAR

- Supply Ability

- 80 Per Week

- Delivery Time

- 5-7 Days

- Main Domestic Market

- All India

- Certifications

- GST, GEM

About PVC Cable Ducts

Owing to our proficiency in this domain, we are offering our clients a wide gamut of PVC Cable Ducts, which is available in various colors and slotting option. It is mainly used in poorly ventilated areas such as aircrafts, rail cars or ships or also in railroad industry. Offered channels are recognized for perfect finish, corrosion resistance, rigid structure, durability, easy and effective cover grip, most economical compared to steel conduits, fire retardant and cost-effectiveness. We offer these PVC Cable Ducts in different specifications as per the needs of clients at very reasonable rates.Excellent Performance and Safety Features

These PVC cable ducts provide outstanding fire safety as they are both fire retardant and self-extinguishing. Their high UV resistance makes them suitable for environments exposed to sunlight, while a smooth surface finish ensures ease of cleaning. With robust insulation resistance and impact strength, you gain peace of mind in high-demand installations.

Versatile Mounting and Modern Design

Offering both screw and adhesive mounting options, installation is flexible for a variety of panel and cabinet designs. The slotted design with a removable cover allows for easy cable organization, access, and future maintenance. The ducts efficient design not only streamlines workflow but also keeps management tidy and accessible.

Quality, Compliance, and Durable Construction

Manufactured from durable, non-conductive PVC, these ducts are RoHS compliant, ensuring they meet stringent environmental standards. While not halogen-free, the material delivers good mechanical load bearing up to 30 kg and maintains less than 5 mm deflection at maximum load, ensuring durability in demanding applications.

FAQs of PVC Cable Ducts:

Q: How are these PVC cable ducts mounted in control panels and cabinets?

A: These cable ducts offer flexible mounting methods, allowing installation using either screws for a secure fit or adhesive strips for quick and efficient setup. This ensures compatibility with various panel surfaces commonly found in electrical and control applications.Q: What benefits does the fire retardant and self-extinguishing PVC provide?

A: The fire retardant and self-extinguishing properties enhance safety by reducing fire risks. In case of fire exposure, the duct will not propagate flames and will self-extinguish, protecting sensitive wiring and minimizing potential damage in electrical environments.Q: When should I select these cable ducts for my project?

A: These ducts are ideal for projects requiring organized wire management in control panels and electrical cabinets, especially where safety, UV resistance, and compliance with RoHS standards are priorities. They perform reliably across a temperature range of -10C to +60C.Q: Where can these PVC cable ducts be used?

A: They are well-suited for use in electrical control panels, industrial automation cabinets, and similar enclosures where reliable cable management and secure routing are essential, even in areas exposed to sunlight or moderate environmental variation.Q: What is the process for installing and maintaining the cable ducts?

A: Installation involves measuring and cutting the duct to the required length, mounting it using screws or adhesive, inserting cables through the slots, and securing the removable cover. Regular inspections and easy access make ongoing maintenance straightforward.Q: What advantages does the slotted removable cover design offer?

A: The slotted design facilitates swift cable entry and routing, while the removable cover allows for easy access during installation or maintenance. This design supports efficient wire organization and future add-ons or adjustments without significant downtime.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry