- Home Page

- Company Profile

-

Our Products

- Electronic Relays

- Advance Feeder Protection & Monitoring Ied : Csezen-f550

- Directional Overcurrent Relay

- AMF Relay

- Frequency monitoring relay series

- Electronic Motor Protection Relay

- IRM-Pro Relay

- PTC Thermistor Relay

- Voltage Monitoring Relay series

- Relay Electronic

- Earth leakage Relay

- Engine Control Relay

- MPR 200nX & 300

- EC 2 AMF Relay

- MN Relay

- RTO Relay

- RX RELAY

- ML Relay

- Current Monitoring Relay

- Ground Fault Module

- SMDBs for Power Distribution

- Low Voltage Switchgears

- ML Contector

- HRC Fuse Link & Base

- Power Capacitor

- Power Quality Solution

- Standard Illuminated Actuator with LED

- Panel Mounted Buzzer

- Electromechanical Timer

- Digital Time

- Digital Timer Digicon

- Gen Next Push Button

- Gen Next LED Indicator

- TPN DB

- SPN DB (Distribution Board)

- Single Phase ACCL

- Surges Protection Devices (SPDs)

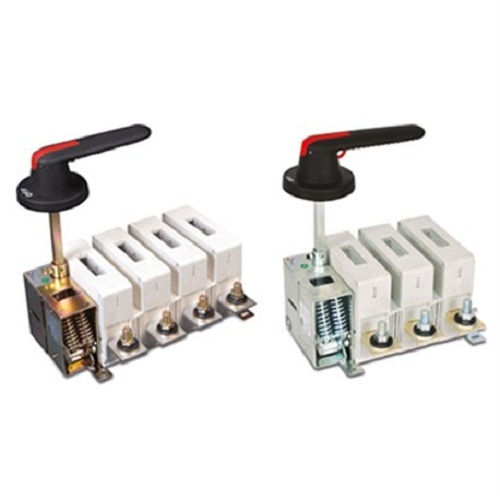

- 4 Pole Isolators

- Servo System

- Programmable logic controller (PLC

- AC Drive

- etaCON M-APFC Controller

- HF fuse DIN-HN Fuse HG and HQ Fuse Bolted

- FNX TPN S-D-F

- FN-TPN S-D-F Suitable for BS Fuse Link

- Type FN S-D-F Suitable for DIN Fuse-link (2P) in Open Execution

- Motor Protection Circuit

- FN-TPN S-D-F in SS Enclosure

- Motorised Changeover

- CONTECTOR 4POLE 25A~125A

- DISTRIBUTION BOARD

- MDX (DC CONTROL)CONTECTOR

- RCCB 2Pole 10-100AMP

- Indicator Lamp

- Fuse Link Cns Off Set Clip In Type 2-20amp

- RCCB 4POLE 10-100AMP

- Hrc Fuse

- Fuse holders suitable for Cylindrical / DIN / Bolted fuse-links

- APFC Controller

- Active Harmonic Filter (AHF)

- PPI DB (Distribution Board)

- Medium Voltage Switchgears

- Circuit Breaker

- Isolators / Mcb

- MCCB (1600AF)

- mccb circuit

- Moter protection circuit Breakers

- Air Circuit Breaker

- Mccb Du/dy

- MCCB 3 POLE 63A-400A

- Mccb Single Pole 16a~160a

- MCCB 4 POLE 63A-400A

- DY 125U MCCBs

- OMEGA Breaker

- C-Power OMEGA Breaker

- Residual Current Circuit Breaker (RCCB)

- Residual Current Circuit Breaker (RCCB)

- MCB 3Pole 6-63Amp

- Mcb 2pole 6-63amp

- Mcb Single Pole 6-63amp

- Mcb 4pole 6-63amp

- Miniature Circuit Breaker (MCB)

- RCCB 1

- SURGE PROTECTION DEVICE

- MCB 2

- Microprocessor Release MicroPro WB

- MCCB Frame S

- WiNbreak2 MCCB

- ACE 2 MCCB

- MCCB - CS Series

- MCCB - CSC Series

- Automatic Changeover With Current Limiter (ACCL)

- MCCB With Thermal - Magnetic Release

- MCCB With Microprocessor Release

- MCCBs for Motor back-up Protection

- Electrical Switches

- 32A Switch Disconnector

- On Load Changover Switch

- one way switch 6A~25A

- SWITCH Disconnector Fuse

- BELL PUSH SWITCH

- Changeover & By Pass Switch

- Switch Disconnector 32a`800a 2p~4p

- Automatic transfer switch

- Change over switch

- Switch disconnector fuse

- FN & C-Line Switch disconnector (2P/TPN/4P)

- changerover switch

- Load Break Switch

- Rotary Switch

- DC Switch salzer

- Time Switches

- POWER UNIT

- Fan Regulator / Dimmer

- Power Bus Trunking

- Power Contactor

- robusTa Power Contactors

- ExceeD Contactor 6A-95A

- MX0(AC/DC)Auxiliary contactor

- MU -2 POLE CONTACTOR

- CAPACITOR DUTY CONTACTORS

- MN0 CONTACTOR (DC)

- MVO (VACUUM)CONTACTOR

- MI CONTACTOR 3POLE

- MX CONTACTOR

- MNX CONTACTOR 3-POLE

- MO CONTACTOR 3-POLE

- Mr Contactor

- MNX CONTACTOR 2 POLE

- CAPACITOR CONTACTOR

- mk1 & MK2contactor

- Power Contactor DX-Series

- Mini Contactors

- D Range Contactors and Overload Relays

- New AGRO 4 Pole Contactor Series

- Electric Socket

- PVC Cable Ducts

- Motor Starter

- Accessories

- Add-on Auxiliary Contact Blocks

- Connecting Links and Mechanical Latch

- Thermal Overload Relays

- Spares and Accessories for type FNX and FN

- SS Enclosure for MCCBs

- Accessories for DU/DY MCCB

- SMDB Accessories

- Accessories of OMEGA Air Circuit Breakers

- Accessories of C-POWER Air Circuit Breakers

- Accessories for Air circuit Breaker

- Accessories for MCCB - CSC Series

- Accessories for Switch Disconnector fuse

- Electronic Relays

- Contact Us

Connecting Links and Mechanical Latch

Connecting Links and Mechanical Latch Specification

- Application Media

- Industrial Lifting, Rigging Applications

- Diameter

- Customized / As Required

- Capacity

- 1 Ton to 25 Ton or as per requirements

- Humidity %

- Up to 95% RH

- Protection

- Corrosion Resistant Finish

- Equipment Type

- Connecting Links and Mechanical Latch

- Temperature Range

- -20C to +80C (Typical)

- Measurement Range

- 1 Ton to 25 Ton

- Connectivity Type

- Mechanical

- Material

- Alloy Steel / Mild Steel / Stainless Steel

- Range

- 1 Ton to 25 Ton (Capacity)

- Shape

- Link Style and Latch Design Based on Application

- Safety Factor

- Minimum 4:1

- Equipment Type

- Connecting Link & Mechanical Latch

- Installation

- Simple Mechanical Assembly

- Surface Finish

- Galvanized / Painted / Powder Coated

- Color

- Red, Yellow, or As Specified by Client

- Usage/Application

- Lifting, Material Handling, Marine, Construction

Connecting Links and Mechanical Latch Trade Information

- FOB Port

- Jaipur,Neemrana,Alwar

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque

- Supply Ability

- Delivery Time

- 5-7 week

- Sample Policy

- Contact us for information regarding our sample policy

- Main Domestic Market

- All India

- Certifications

- GEM&GST

About Connecting Links and Mechanical Latch

Features of Mechanical Latch

1. Suitable for sites where voltage fluctuation is frequent

2. Saves energy as coil supply can be removed once contactor is picked up

3. Ideal for logical operations

4. Keeps contactor in closed condition even after removal of coil supply

Durable and Corrosion-Resistant Design

Our connecting links and mechanical latches are available with galvanized, painted, or powder-coated finishes, ensuring long-lasting protection against environmental elements. Engineered for rigorous industrial use, these products resist corrosion and maintain structural integrity under high stress and extreme conditions, crucial for safety in lifting and rigging operations.

Versatile Solutions for Multiple Industries

Suitable for lifting, material handling, marine, and construction environments, our links and latches are crafted from alloy, mild, or stainless steel to meet specific project requirements. With customizable shapes and diameters, they adapt seamlessly to various rigging setups and equipment types, providing secure performance across a range of industrial applications.

Simple Installation and Customizable Features

Designed for easy mechanical assembly, our connecting links and latches save on installation time and labor costs. Color options such as red, yellow, or client-specific selections help in quick identification and compliance with safety protocols. Each component can be tailored to meet unique capacity, dimension, and operational needs.

FAQ's of Connecting Links and Mechanical Latch:

Q: How are the connecting links and mechanical latches installed?

A: Installation involves a straightforward mechanical assembly process, allowing for swift and secure attachment to chains, ropes, or other hardware in the lifting or rigging setup. No specialized tools are typically required, making on-site installation efficient and hassle-free.Q: What materials and surface finishes are available for these components?

A: The links and latches are offered in alloy steel, mild steel, or stainless steel, with surface finishes including galvanized, painted, or powder coated. These options enhance corrosion resistance and durability, making the hardware suitable for challenging industrial and marine environments.Q: When should I choose a customized diameter or design?

A: Customized diameters and link/latch designs are recommended when specific load capacities, compatibility with existing equipment, or unique application requirements dictate non-standard dimensions or shapes. Our team can assist with tailored solutions to fit your precise needs.Q: Where are these products commonly used?

A: These connecting links and mechanical latches find applications across various sectors such as industrial lifting, material handling facilities, marine operations, construction sites, and rigging activities, owing to their strength and reliability.Q: What is the benefit of choosing a minimum 4:1 safety factor?

A: A 4:1 safety factor ensures that the component can handle loads up to four times its rated working load, providing enhanced safety and reliability in critical operations involving heavy lifting or high-stress situations.Q: How does the corrosion-resistant finish benefit the end user?

A: Corrosion-resistant coatings like galvanization, paint, or powder coating provide sustained protection against rust and environmental wear, reducing maintenance frequency and extending service life, especially in humid or marine conditions.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Accessories Category

Accessories of C-POWER Air Circuit Breakers

Minimum Order Quantity : 6 Piece Pieces

Power Supply : 110V/220V/415V AC/DC (as per model)

Material : Engineering plastic, Copper contacts, Steel frame

Display Type : Other, LED, LCD for status indication

Equipment Type : Air Circuit Breaker Accessory

Thermal Overload Relays

Power Supply : Three Phase 415V AC

Material : Flame Retardant ABS Plastic / Silver Contacts

Display Type : Other, Mechanical Trip Indicator

Equipment Type : Thermal Overload Relay

Accessories for Switch Disconnector fuse

Power Supply : Not Applicable (Accessory Items)

Material : High Grade Plastic and Metal Combinations

Equipment Type : Accessories for Switch Disconnector Fuse

Accessories for DU/DY MCCB

Price 10168 INR / Piece

Minimum Order Quantity : 100 Pieces

Power Supply : Electric

Material : SS

Display Type : Digital, Other

Send Inquiry

Send Inquiry